TUBE BENDING

Tube bending has never been more important as new and challenging designs of balustrades and staircases have requirements for bends and sweeping bends. With decades of experience in tube bending we have the foresight and technological edge needed to deliver high-quality tube bends at scale or on a one-off basis. Regardless of the size of order, we offer an efficient turnaround on all tube products.

METAL FINISHING

Metal finishing is an extremely important part of metal product fabrication as it can alter the durability, chemical and weather resistance capabilities a product. Finsa Supplies are often called upon to undertake diverse and complex architectural metalwork projects where raw metals such as steel need to undergo “finishing” in order to be better prepared for the environment in which they will be installed. Although steel and other engineering metals are durable and tough, their resistance ability often needs to be enhanced.

BRUSHED POLISHING

We offer a refined brushed polishing service suitable for a number of metalwork applications. Brushed metal can give architectural metalwork a character, personality and distinctive sleekness. Finsa Supplies has many construction projects with fine brushed metal products, contributing to the timeless classic look of many features in buildings and facilities across thousands of sectors.

METAL DRILLING SERVICES

Finsa Supplies offers reliable drilling services for a wide range of architectural metalwork and structural steel products. Due to our precise and stringent drilling processes, you can have full confidence our products are secure, durable and hard-wearing once installed.

PRESS BRAKING

Press braking is a significant part of the entire metal fabrication process and it is crucial that any press brake service is offering a combination between the highly trained operators and precise machinery capable of delivering high-quality bends. At Finsa Supplies Engineering we have in excess of half a century of press braking experience which has contributed greatly to the many different metal fabrications we have delivered to clients over the years. We pride ourselves on producing the most accurate metal pressings which can be used in a number of different applications.

CUTTING

At Finsa Supplies we are proud to offer a whole range of professional metal cutting services that deliver a clean tidy cut every time. As a professional end-to-end steel fabrication company, we understand that physical cutting needs to use the toughest best-performing hardware available. This is why the amazing skills of our cutting team are augmented by the latest industry equipment delivering fast turnarounds and great value.

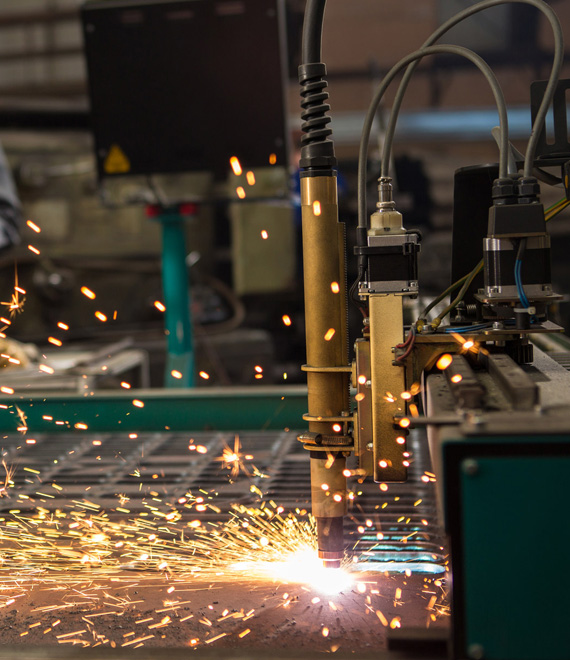

PLASMA CUTTING

Plasma cutting is one of many cutting methods we employ at Finsa Supplies as part of our extensive steel and metal fabrication offer. With a workforce of trained and experienced plasma cutting specialists, you can be sure that your requirements will be carried out to a high standard.

WELDING

At Finsa Supplies we believe that quality welding underpins the structural integrity of any project large or small irrespective of client or sector. We know that as a customer, you need to be 100% sure that any welding service you use must be thorough, detail-oriented and of the highest quality in order to guarantee long-term durability.

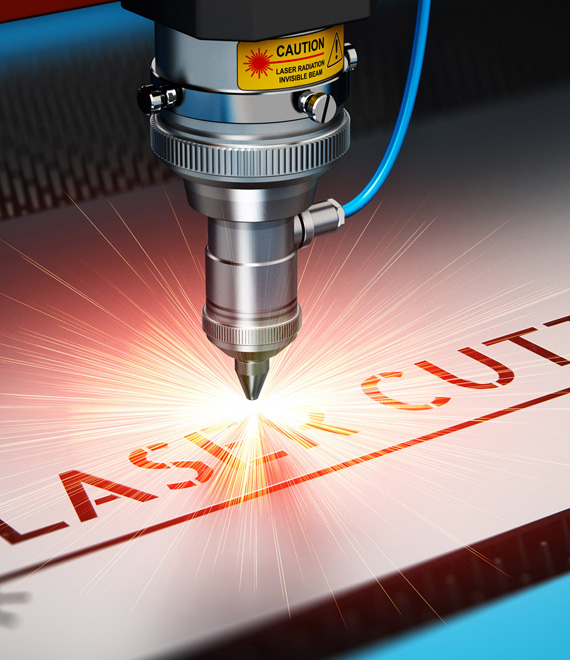

LASER CUTTING

Finsa Supplies offers a full laser cutting service as part of our already extensive in-house steel fabrication capability. Using the latest fibre optic and gas cutting technology we can deliver accurate, timely and immaculate fabrication work. We seek to offer our clients the benefits of laser cutting with a devoted consultative approach with also offers added value for money.

METAL FOLDING

Metal folding is a way of quickly forging large metal products into a desired shape using powerful machinery. Metal folding is a widely used process used to fabricate a wide range of beams, joists, parallel flange channels and other structural metals. Metal folding can be performed using a variety of methods, including manual folding, brake pressing, and roll forming. Manual folding is typically done by hand using a bending tool, while brake pressing and roll forming use specialised machines to fold the metal.